Solo 990

适合于精准的手部活动

-

CAT. 3

0334

0334

-

VIRUS

VIRUS

具体优势

舒适度

舒适度

- 精准灵巧: 减少手套厚度

保证质量

保证质量

- 无硅树脂,防止金属板和玻璃在喷漆前存在痕迹和瑕疵

实用性

实用性

- 容易穿戴和脱去

- 适用于短时间使用的防护需求

应用行业

汽车/机械行业

- 小零件装配

食品工业

- 罐头加工制造

- 食品处理

- 食品制备

- 制备和封装

- 封装

产品详情

| 材质 | 聚氯乙烯 |

|---|---|

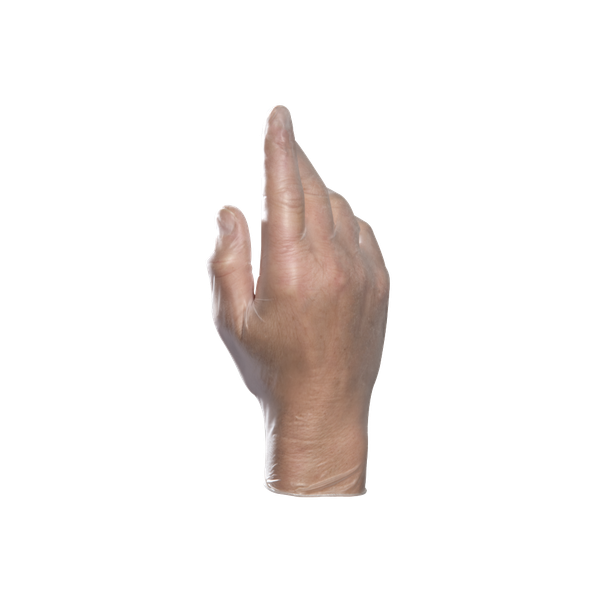

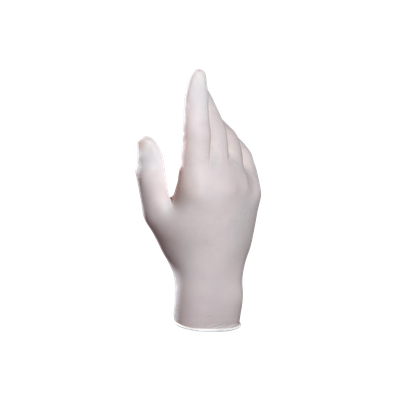

| 颜色 | 白色, 透明的 |

| 内表面工艺 | 无粉 |

| 外表面工艺 | 光滑的 |

| 长度 (cm) | |

| 尺码 | 6 7 8 9 |

| 包装 | 100 手套/盒 1000 手套/箱 |

| AQL | 4.0 |

化学含量表

综合化学防护等级

防护等级是通过渗透和降解两方面的性能表现来决定的,为使用我们手套产品的用户提供针对特定化学品的总体防护指南。

指代颜色

用于高化学暴露或化学浸泡,穿透时间以一个工作日为限。

用于化学品反复接触,限于化学品接触总时长,即以工作日为基础的累积渗透时间。

仅防溅,接触化学物质时应丢弃手套,并尽快戴上新手套。

不推荐,这些手套被认为不适合与这种化学品接触。

NT : 未经测试

NA:“不适用”,因为没有全面测试(只有降解或渗透结果)

化学试验数据和整体化学防护等级不应作为手套选择的绝对依据。实际使用条件可能会因实验室测试的受控条件而改变手套的性能。除了化学接触时间以外的因素, 如浓度和温度、手套厚度和手套的重复使用,也可能影响性能。手套的其他要求,如尺码,灵巧度,防割性,耐磨性,抗刺穿和钩阻力, 或手套的抓握力也需要在最终选择前纳入考虑。

| 化学物质 | CAS # | 渗透时间 (分钟) |

渗透水平 | 标准 | 老化水平 | 级别 |

|---|---|---|---|---|---|---|

| Hydrogen peroxide 30% | 7722-84-1 | >480 | 6 | EN 16523-1:2015 | NT |

|

| n-Butanol 99% | 71-36-3 | 1 | 0 | EN 374-3:2003 | NT |

|

| Sodium hydroxide 20% | 1310-73-2 | >480 | 6 | EN 374-3:2003 | NT |

|

| Sodium hydroxide 40% | 1310-73-2 | >480 | 6 | EN 16523-1:2015 | 4 |

|

| Sodium hydroxide 50% | 1310-73-2 | >480 | 6 | EN 374-3:2003 | NT |

|

| Sulfuric acid 96% | 7664-93-9 | 22 | 1 | EN 374-3:2003 | NT |

|

*非标准化结果